Explore Aotumedoll's Journey from Design to Finished Product

I was very happy to go on this exploration trip to the Love Doll Factory, which allowed me to discover many details that are usually difficult to understand using a computer alone. The production of sex dolls is not a simple assembly line project. From the initial image design, body structure to skeleton production, and then to the final casting and molding, every link embodies the hard work of the producers and designers. This factory trip allowed me to personally experience the production process of real sex doll, gain an in-depth understanding of the process of head design and discussion, and witness how love doll was born from zero to one. This is not only a journey of exploration, but also a tribute to the spirit of craftsmanship.

The following content will take you through my aotumedoll exploration journey. Although it cannot cover all the details, I hope it will allow you to experience this unique journey and the unique charm of the doll-making process from a side perspective.

Factory Environment and Atmosphere

Most of the factories producing sexdoll are located in Dongguan City, Guangdong Province, China, which is a world-renowned manufacturing center. As soon as you arrive at the aotumedoll factory gate, you can feel the strong industrial atmosphere: neat factory buildings, busy logistics vehicles, and eye-catching brand logos, all of which demonstrate the efficiency and professionalism here.

Walking into the production workshop, what comes into view is a well-organized scene. The workshop is well-lit, the environment is clean, and every detail has been carefully planned. From skeleton assembly to facial makeup, each process has a dedicated area and tools, and the workers perform their duties and concentrate on completing the tasks at hand. Their movements are skillful and precise, as if they are carving pieces of art, rather than simple assembly line products.

This simple and wonderful production life is the core of the birth of lovedoll. Behind each doll, the workers' ingenuity and enthusiasm are condensed.

Production Process Overview

Step 1: Skeleton Making

Before entering the factory, I thought that the making of the sex doll started with fixing the mold, but the real starting point is the creation of the skeleton and the making of the mold.

Workers use professional equipment to cut and weld steel to make skeletons that meet specific body shape requirements. The choice of skeleton is crucial to the overall quality and durability of the love dolls. Today's sexdoll skeletons have been upgraded from early low-cost materials to more solid black iron and spring steel, which not only enhances durability, but also improves joint mobility, making the doll more flexible.

It is worth noting that the skeletons of TPE and silicone are not the same. Since TPE is softer than silicone and has a different weight, the joint mobility and fixing method of the skeleton need to be adjusted accordingly to ensure the feel, durability and flexibility of the final product are optimal.

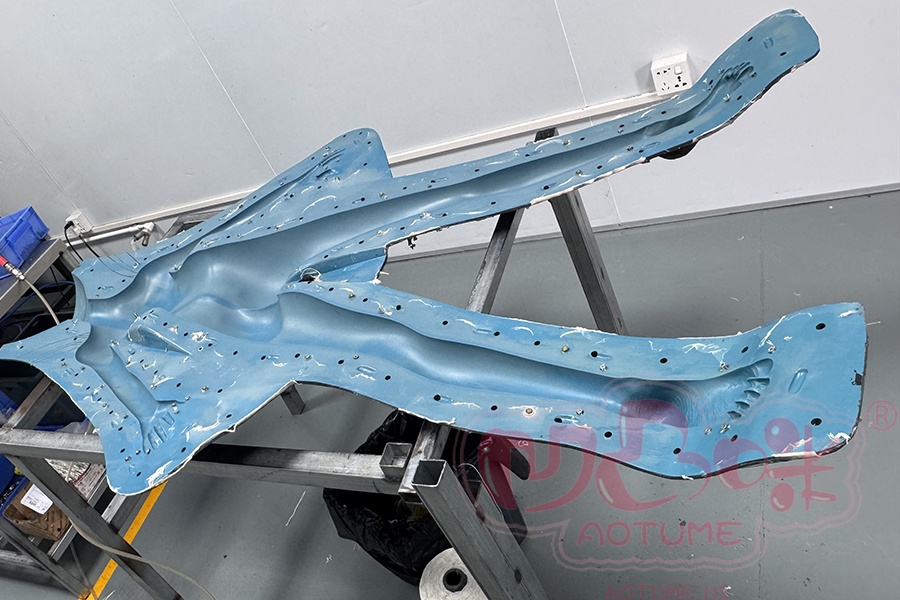

Step 2: Fix the Frame

After the frame is made, the next step is to fix it inside the mold. Workers use thin iron wire or cotton thread to accurately fix the frame in the mold. This process seems simple, but it is actually crucial. A loosely fixed frame may be misaligned during the subsequent pouring process, causing structural problems in the final product. Therefore, each link needs to be strictly inspected and adjusted to ensure the accuracy and durability of the final product.

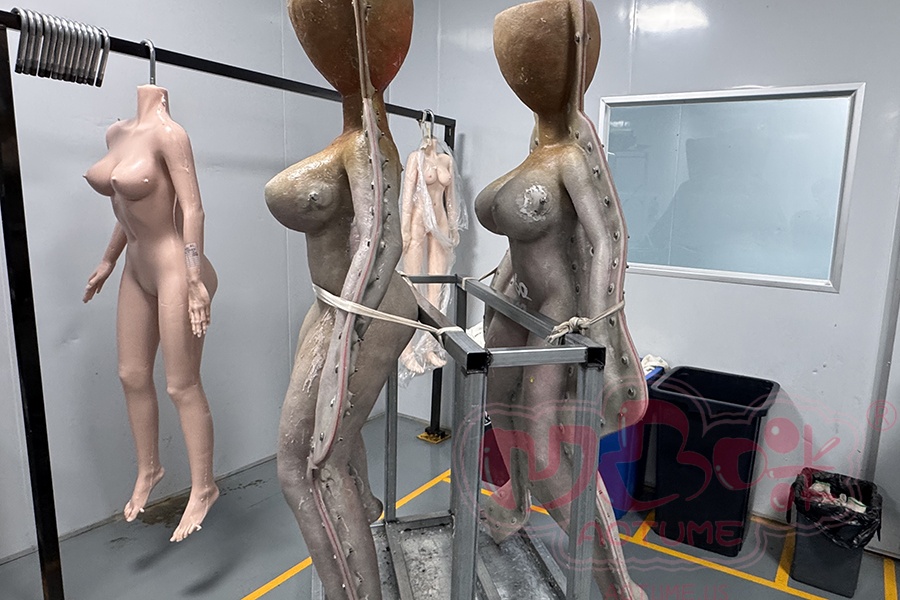

Step 3: Material Casting and Trimming

Love doll are made of two main materials: silicone and TPE, each with its own advantages and disadvantages, and different production processes.

Silicone Casting:

Silicone is a cold-forming material, and once cast, it cannot be repaired. Therefore, during the production process, workers need to precisely control the fluidity of silicone, and use professional tools to trim the seams after casting to ensure a smooth and flawless surface. In addition, in order to reduce the weight of silicone products, many manufacturers have introduced foam weight reduction technology. This technology not only maintains the real touch of silicone, but also reduces the overall weight, giving customers a better experience when using it.

TPE Casting:

The production process of TPE is different from that of silicone. It needs to cool down overnight before it can be fully formed. The advantage of TPE is its repairability. Even if there are minor defects during the production process, it can be reshaped by heating. When trimming the seams, workers will use electric welding tools to iron them to ensure a smoother and more natural surface.

About Silicone and TPE

TPE (thermoplastic elastomer) and silicone are two commonly used materials for dolls, each with its own advantages and disadvantages, suitable for different needs.

- Touch and softness

TPE is softer, feels closer to human skin, and deforms when pressed, suitable for users who like soft touch. Silicone is tighter, has a finer surface, and has a more realistic skin texture, suitable for people who pursue realism. - Durability and repairability

Silicone is more durable, not easy to age or deform, but difficult to repair after damage. TPE is relatively fragile, but small defects can be repaired by heating. - Weight and portability

TPE has a lower density, so the doll is lighter and easier to carry. Silicone is heavier, and although it increases the sense of reality, it is more difficult to move. - Cost and price

TPE has a lower cost and is more affordable, but requires more careful maintenance. Silicone is more expensive, but has a longer lifespan and lower long-term use costs. - Maintenance

TPE easily absorbs dust and grease, requires regular cleaning and care, and has poor heat resistance. Silicone is easier to clean, has strong heat resistance, and is not easy to deform.

Summary TPE is suitable for users with limited budgets and who pursue a soft feel, while silicone is suitable for users who pursue durability and a more realistic appearance. You need to weigh your personal needs when choosing.

The following is a detailed explanation of silicone and TPE: AotumeDoll Silicone and TPE

The following is a comparison of TPE and silicone: (TPE material on the left, silicone material on the right)

Step 4: Body Makeup Drawing

There are differences in body makeup drawing between different brands of lovedoll. Taking the aotumedoll brand as an example, its body makeup is mainly reflected in the makeup on the face. Through fine drawing, the real doll is closer to the anime character.

Workers will hand-paint the eyebrows, eyelashes, mouth shape and other facial details of the love doll, and at the same time finely color the areola, joints, lower body and other parts to ensure that the skin color is more natural and avoid making the body look too stiff or abrupt.

It is worth mentioning that aotumedoll's sex doll is equipped with a unique "tracking function" eyeball. This eyeball is made of glass and has a convex design. No matter from which angle you look at it, the eyes seem to be looking at you. The use of this technology greatly enhances the realism and interactivity of the sex dolls.

However, it should be noted that the eyeballs matched with different head shapes and face shapes are specific. When installing, it is necessary to strictly distinguish between the left and right eyes and adjust the strength to ensure the fit and naturalness.

The following are the eye makeup drawing and areola, lower body and upper body workrooms:

Detailed explanation of the tracking function: Aotume Doll Eye Tracking Function Demonstration

The following are pictures showing the close-up of the eyeballs:

Step 5: Assembly and Confirmation Before Shipment

Before final shipment, the factory will perform final assembly and confirmation.

The workers will assemble the head and body, take photos and send them to the customer for confirmation to ensure that the overall appearance of the doll meets the requirements. After obtaining the customer's confirmation, the workers will wrap the head and body with foam material and put them in a customized packaging box to ensure that they will not be damaged during transportation.

Features and Advantages of Aotumedoll

Aotumedoll is a high-end handmade custom 2D humanoid doll. With its exquisite craftsmanship and excellent performance, it has become an ideal choice for doll lovers. Whether it is material, design, or functional experience, Aotume Doll perfectly meets your needs.

First of all, Aotume Doll uses soft and elastic material, the head and body are comfortable to touch, and there is no color difference. The mold line is finely processed to ensure that every detail is impeccable. Its characteristics of less oil, no odor, tear resistance, and strong toughness make the doll more durable and can maintain good condition after long-term use.

Aotumedoll's facial makeup is all hand-painted by craftsmen. The solid makeup process ensures that the makeup will last for a long time. The tracking design of the eyeballs makes the doll's eyes more vivid and agile. Users can also easily replace the eyeballs to add interactive fun.

In addition, Aotume Doll is equipped with the latest stainless steel alloy skeleton, which has both strength and flexibility, and supports upgrading to 20-joint finger bones, bringing richer action performance. The doll also adopts weight reduction technology to reduce the overall weight while keeping the body soft, which improves the user's hand-held experience. The strong clamping and suction vagina design of the silicone upgrade further enhances the realism and interactivity of the doll.

Aotume Doll's head shape and body shape are specially designed for the two-dimensional style. The styles are diverse and light, and it is suitable for ordinary one-size-fits-all wigs. You don't need to worry about the size of the wig. More importantly, Aotumedoll also provides character customization services, which can customize expressions and shapes according to your preferences, and perfectly restore the character image in your mind.

Whether you are a fan of the two-dimensional culture or a doll collector, Aotume Doll is your best choice. Its exquisite craftsmanship, high-quality materials and thoughtful service will definitely bring you the ultimate user experience.

Unique Craftsmanship Makes the Perfect Love Doll

This factory tour made me deeply appreciate the complexity and fineness of the sex doll production process. From skeleton production to material casting, to the final detail polishing and body makeup painting, every step requires the craftsmen to concentrate and carve meticulously. They are not just making a product, but giving the doll a soul, making it closer to reality and giving it vitality.

The production of love dolls is not only an industrial production, but also a manifestation of art. The polishing of every detail, the selection of every material, and even the adjustment of the angle of the eyeballs require professional technology and strict quality inspection to ensure that the final product can reach the best state. It is this extreme pursuit of details that allows real doll to present such realistic visual effects and excellent feel.

If you are interested in love dolls, I hope this article will not only let you understand its production process, but also let you feel the craftsmanship and unique charm contained in it. Maybe next time, when you see an exquisite love doll, you will also respect the craftsmanship and efforts behind it.